Aluminum profiles are a crucial component in different markets due to their adaptability, toughness, and light-weight nature. Among the most acknowledged uses of aluminum profiles is in window and door production, where aluminum extrusion profiles supply an equilibrium in between sturdiness and looks.

Aluminum profiles for solar panel mounting have gotten substantial traction as the need for sustainable power sources proceeds to rise. Furthermore, due to the fact that aluminum is completely recyclable, it straightens with the sustainable methods urged in the solar industry, making aluminum profiles for solar mounting not simply useful yet also ecologically pleasant.

Industrial applications have also widely embraced aluminum profiles due to their remarkable homes. These profiles are typically integrated with CNC machining aluminum profiles, which additionally enhance their functionalities by offering precision-engineered components that dramatically add to modern-day production processes.

In the realm of thermal monitoring, extruded aluminum heatsinks supply vital solutions to maintain electronic devices and mechanical systems cool. As tools end up being much more small and powerful, effective warmth dissipation ends up being necessary to keep performance and stop damage. Extruded aluminum heatsinks are characterized by their high thermal conductivity and light-weight characteristics, making them an optimum option for cooling applications in different digital and industrial gadgets. The capacity to personalize these heatsinks through CNC machining permits customized designs that fit certain spatial constraints and warm diffusion requirements, thus ensuring effective procedure.

One more interesting development in the field of aluminum extrusions is the development of T-slot aluminum extrusions. The modularity of T-slot systems produces plenty of configuration opportunities, streamlining the style process and helping with changes as demands advance.

Standard aluminum extrusion profiles serve as the backbone for plenty of applications across various sectors. The adaptability of aluminum extrusion, combined with the accessibility of standard profiles, suggests that companies can enhance their production processes, reduce lead times, and preserve high-grade outcomes.

Custom aluminum extrusion profiles use services the chance to develop tailored remedies that specifically fulfill their special specs. Manufacturers that specialize in producing custom aluminum extrusions can accommodate a vast variety of finishes, measurements, and shapes, opening up new methods for style creativity.

In the world of looks, architectural aluminum extrusion profiles contribute significantly to modern-day building styles. From sleek façades to vibrant structural aspects, these profiles lend themselves to cutting-edge architectural attributes. The capability to anodize aluminum surface areas improves both the visual charm and durability of the profiles, adding a layer of defense against deterioration and surface wear. This surface not only prolongs the life-span of the profile but likewise offers a myriad of color alternatives, enabling engineers to attain a cohesive layout visual that lines up with their vision.

Automotive aluminum extrusions are crafted to satisfy specific efficiency requirements, including crash safety and security and mechanical stamina while decreasing total automobile weight. The recyclability of aluminum supports lasting advancement goals, making it a recommended material in modern automotive layout.

The aerospace industry, understood for its rigid needs and performance standards, has likewise located aluminum extrusions to be unbelievably valuable. The evolutionary nature of aluminum style allows aerospace designers to develop innovative structures that enhance general aircraft performance.

For recreation applications, boats aluminum extrusion profiles give the architectural integrity needed to endure varying environmental conditions while adding to weight savings that improve performance on the water. The usage of aluminum in marina and boating applications has actually gotten appeal because of its resistance to rust from deep sea, making it an exceptional choice for resilient sturdiness on private yachts and boats. The lightweight yet strong features of aluminum enable enhanced speed and handling, enriching the overall boating experience.

Aluminium frame manufacturers supply a mix of layout convenience and efficiency, making it possible for a variety of products to be developed for various industries. From greenhouses to event click here stands and mechanical settings up, aluminum frameworks provide durable support while permitting simplicity of assembly and alteration. The uniform homes of aluminum ensure that these structures will supply constant performance while keeping manufacturing expenses convenient because of quick manufacturing procedures.

As we want to the future, technical developments and sector developments will certainly continue driving the advancement of aluminum profiles and extrusions. The continuous advancement of CNC machining techniques additionally boosts the abilities of aluminum profiles, enabling remarkably elaborate designs that were previously not practical. Additionally, the growing need for sustainability practices will press for extra efficient production procedures and better recycling efforts within the aluminum industry.

Provided the large range of applications for aluminum profiles-- from building and automotive to aerospace and renewable energy-- it's clear that these products are important to modern-day infrastructure, technology, and sustainable advancement. By leveraging the one-of-a-kind properties of aluminum and utilizing the power of sophisticated manufacturing methods, markets can proceed to check out brand-new frontiers and push the limits of efficiency, design, and performance. Aluminum extrusion continues to be a foundation of modern manufacturing, adding to read more ingenious solutions that fulfill society's developing demands.

Michael Bower Then & Now!

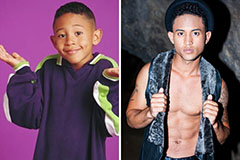

Michael Bower Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!